This section contains our most common staircase construction methods and the styles that will suit.

Riser

Closed Rise

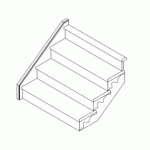

A Closed Rise staircase is the standard construction for a timber staircase, by having the treads closed it allows the space beneath the staircase to be used for storage. This sort of construction is most commonly used by budget conscious builders and low-income clients.

Open Rise

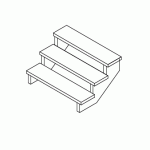

An Open Rise staircase is defined as a staircase in which has the riser board is removed to create an opening through the staircase. These are most commonly used in a foyer as they allow the viewer to see straight through the staircase into the rest of the home.

Stringer

Closed Stringer

A Closed string staircase is the most cost effective construction method, the treads and risers are grooved into the stringer and then glued & wedged to create a solid flight.

Closed Rise/Closed Stringer

Open Rise/Closed Stringer

Cut Stringer

Cut String staircases are used when the client wants see the end-grain detail of the treads and/or risers. A Cut stringer is defined as a stringer, which is cut in a sawtooth fashion to allow the treads to overhang the stringer.

Capped Cut Stringer

Closed Rise/Cut Stringer

Cut stringer with Frets

Open Rise/Cut Stringer

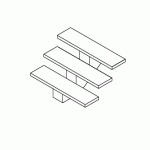

Mono Stringer

Mono-stringers stair designs tend to be one of the more expensive construction methods. As they are open in design. The stringer itself tends to be less apparent due to its located centrally and underneath the treads themselves. The ability of mono-stringer to promote a sense of lightness and openness is regarded as a desirable property. When compared to traditional closed or enclosed stairs, mono-stringers demand the use of relatively stronger materials in order to be structurally sound.

Steel Stringer

By using dual steel stringers, the staircase is allowed a sleeker look, because of the strength difference between Steel and Timber you can obtain a cleaner fixing. More often than not, this design is part of an open rise construction and is most suited to modern homes.

Curved Stringer

Curved Staircases are one of the most labour intensive build’s requiring a complete 1:1 replica of the clients wall to be constructed in our factory. The construction of a common curved staircase requires in excess of 25+ hours of labor.

Tread Nosings

The treads are the material on which you walk, at OzStair we offer 5 basic nosing profiles which can be used to change the style of your staircase to match the surroundings.

A half round nosing is defined by having two partially rounded edges with a flat surface between this flat surface creates a desirable look which can be used on virtually any surface and so is easily repeated.

A full round nosing is easily noticeable due to the fact that it contains a continuous curve on the front edge of the nosing. This is the most common design choice when producing a staircase due to the ease of creating this profile.

A pencil round nosing is designed to match the curve of pencil at the exposed edge’s of a tread. See above for an Example.

A square aris nosing is typically used with a modern style construction staircase. This detail is characterized by its sharp lines which are created by giving the edges only a 1-2mm champher providing the contemporary look that is highly sought after.

A staircase with no nosings is generally constructed using a combination of Pine and MDF this is due to the availability of MDF components and their cost effectiveness. This means that when we are requested to construct a staircase for use with flooring materials we will provide a timber frame ready for you to lay the material on. e.g. Timber strip flooring.